Sludge Mechanical Dewatering Equipment

Process principle

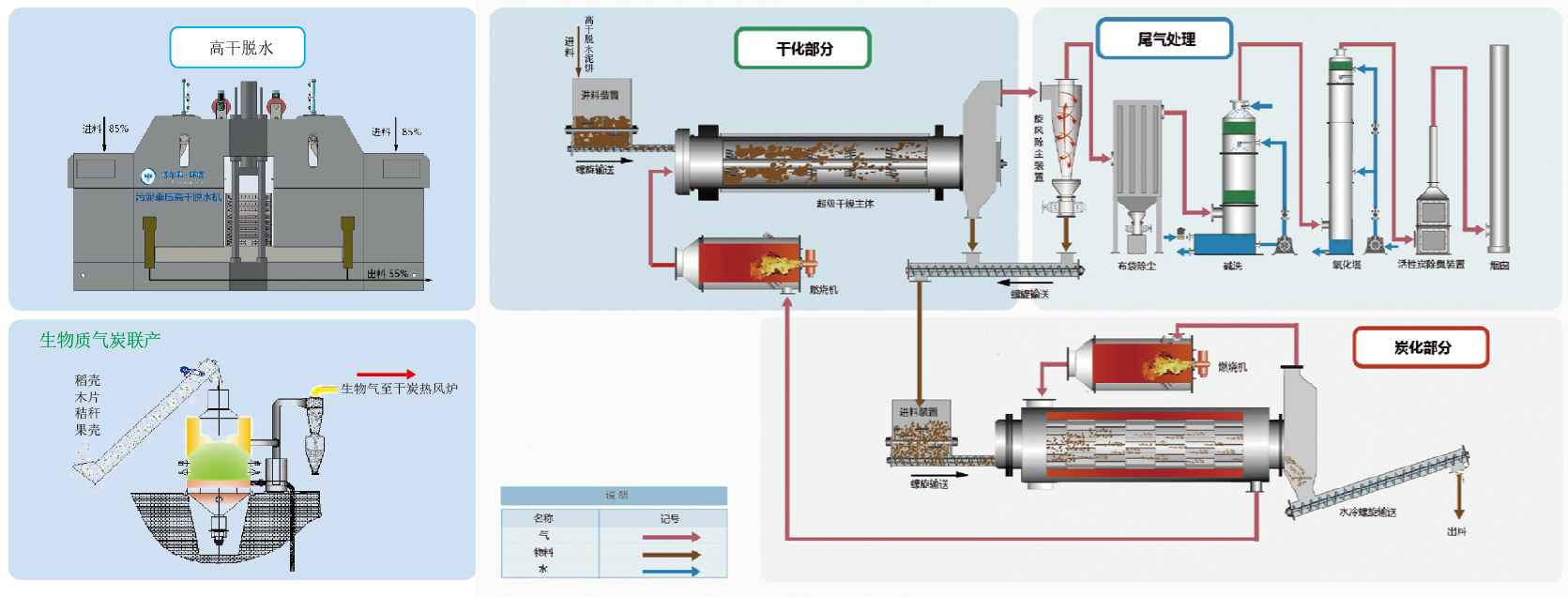

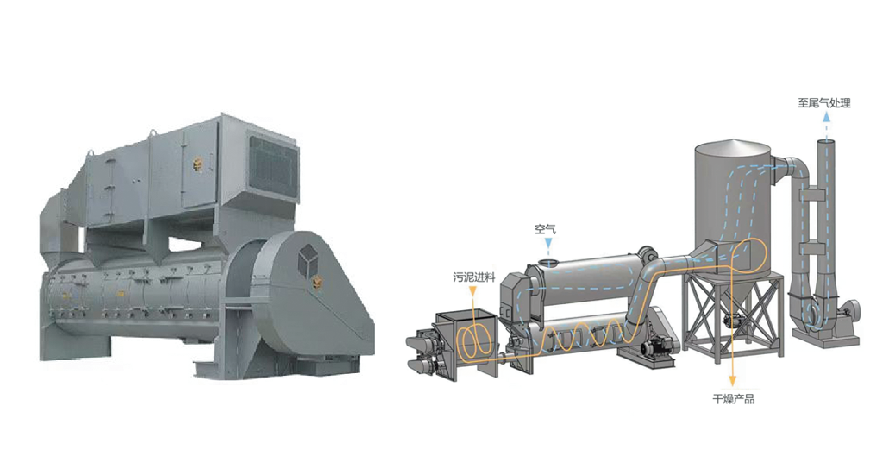

Dryer: Sludge is crushed into 0.5 – 5 mm particles and treated at 100°C using high-temperature airflow and optimized wind speed. Cold air purification reduces humidity by 25%.

Carbonization Furnace: Sludge is heated in a jacketed reactor, and under anaerobic conditions, the sludge is pyrolyzed in the range of 400-600℃.The produced combustible tail gases such as H2, CO, and oil and gas are secondary burned, purifying the flue gas while achieving energy recovery to provide the heat needed for carbonization. The dried sludge is ultimately converted into carbonized material.

Integrated Drying-CarbonizationSystem: High-temperature exhaust gases from carbonization are reused for drying, minimizing heat loss and eliminating the need for additional gas treatment systems.