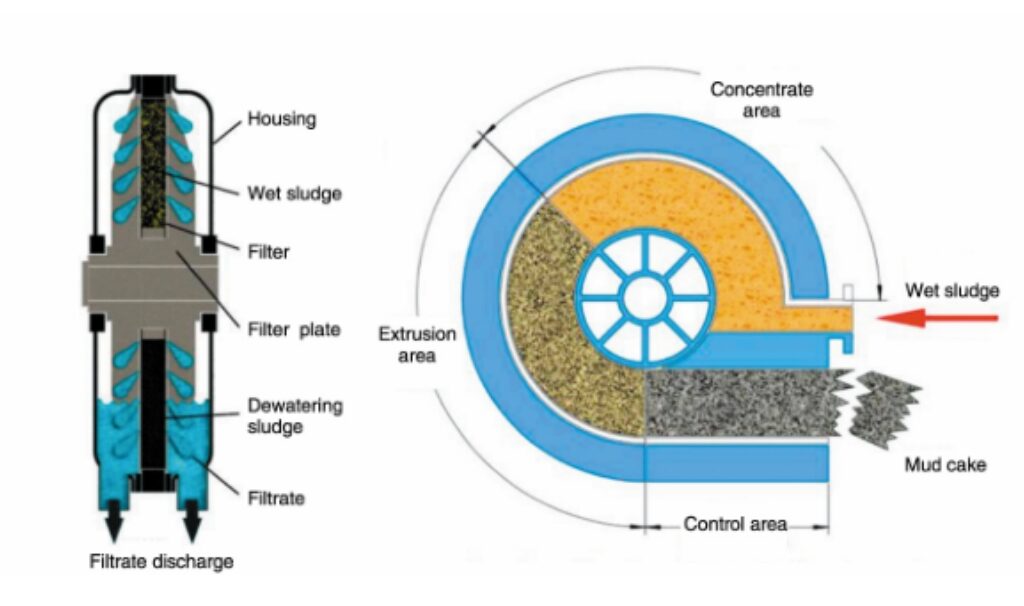

Rotary Press Dewatering

Working Principle:

Sludge treated with specific chemicals enters the C-shaped internal channel at a certain pressure and rotates between two parallel stainless steel filter mesh units. Meanwhile, the free water from the sludge is expelled through the mesh, and the sludge is continuously pushed towards the discharge outlet by friction. At the same time, under the restriction of the outlet, high dehydration of sludge is ensured.

1、Continuous and stable operation.

2、The equipment is fully enclosed, with controllable Feed sludge

odor sources.

3、Fully automated, unattended, and capable of intelligent control.

4、 Few parts, no wear components, and low maintenance costs.

5、Programmed backwashing of the filter maintains its high efficiency and cleanliness.

6、The entire equipment is made of stainless steel, offering corrosion resistance and a long lifespan.

7、The equipment operates at low speed (0.2-2 rpm),with low noise and eco-friendly.

8、The equipment has a small footprint, allowing for easy upgrade and iteration of traditional dewatering equipment without the need for new land or structures.

9、The specialized curing agent can be produced in large quantities, priced similarly to traditional PAM,and has low operating costs.

10、The treated sludge has a moisture content of 60-70%, achieving high-efficiency dewatering through continuous operation, with low subsequent disposal costs.